Digital Plating Platform: A Revolutionary Approach for High-Throughput Microbial Analysis and Antibiotic Discovery

This article explores the digital plating (DP) platform, a transformative technology that integrates traditional microbiology with cutting-edge digital bioassay and microfluidic principles.

Digital Plating Platform: A Revolutionary Approach for High-Throughput Microbial Analysis and Antibiotic Discovery

Abstract

This article explores the digital plating (DP) platform, a transformative technology that integrates traditional microbiology with cutting-edge digital bioassay and microfluidic principles. Tailored for researchers, scientists, and drug development professionals, we detail how this platform overcomes the limitations of conventional culturing by enabling rapid, single-cell-resolution analysis. The scope covers foundational principles, diverse methodological applications from antibiotic susceptibility testing to single-cell isolation, strategies for troubleshooting and optimization, and rigorous validation against established techniques. By synthesizing the latest research, this article serves as a comprehensive guide to leveraging the DP platform for accelerated microbial detection, phenotypic characterization, and high-throughput screening in biomedical and clinical research.

Beyond the Petri Dish: Understanding the Core Principles of Digital Plating Technology

Traditional plate culturing remains the “gold standard” in microbiology laboratories, providing a reliable and well-established framework for isolating, identifying, and quantifying microorganisms from various environmental, clinical, and industrial samples [1]. Despite its foundational role in microbiology, this method faces significant critical limitations that hinder modern diagnostic and research workflows. These constraints primarily include prolonged incubation times ranging from 18 to 72 hours, labor-intensive serial dilutions and manual spreading techniques that limit scalability, and the obscuring of rare or slow-growing taxa due to interspecies competition in mixed samples [1]. Furthermore, traditional methods rely predominantly on colony morphology and population-level metabolic profiling, failing to differentiate intercellular genetic and phenotypic variations [2]. This inherent limitation potentially disregards microbial heterogeneity and obscures crucial biological insights, particularly for rare cell subtypes or slow-growing organisms that are often outcompeted by faster-growing species [2].

The emergence of innovative technologies, particularly digital plating platforms and microfluidic systems, addresses these constraints by integrating the principles of traditional culturing with cutting-edge digital bioassay technology [1]. These advanced systems enable rapid isolation, quantification, and phenotypic characterization of microorganisms at single-cell resolution, significantly accelerating microbial detection and analysis while providing unprecedented resolution for studying cellular heterogeneity [1] [3]. The following sections detail the specific limitations of traditional methodologies and present quantitative comparisons with emerging technologies, along with detailed protocols for implementing these advanced platforms in microbiological research.

Quantitative Comparison: Traditional vs. Digital Methods

Table 1: Comparative Analysis of Microbial Cultivation and Screening Platforms

| Platform Characteristic | Traditional Plate Culturing | Digital Plating (DP) Platform | AI-Powered Digital Colony Picker | Droplet Microfluidics |

|---|---|---|---|---|

| Time to Detection | 16-24 hours (E. coli) [1] | 6-7 hours (E. coli) [1] | Not specified | 5 hours (Salmonella detection) [2] |

| Single-Cell Resolution | Limited [1] | Yes [1] | Yes [3] | Yes [2] |

| Throughput Capacity | Low, limited by manual processes [1] | 113,137 microwells per chip [1] | 16,000 microchambers per chip [3] | 28,000 droplets per hour [4] |

| Antibiotic Susceptibility Testing Time | Typically 16-24 hours [1] | <6 hours [1] | Not specified | Not specified |

| Isolation of Rare Taxa | Limited by interspecies competition [1] | Enabled via compartmentalization [1] | Enabled via AI-driven identification [3] | Enabled via single-cell encapsulation [2] |

| Automation Potential | Low, labor-intensive [1] | Moderate [1] | High, fully automated [3] | High [2] |

Table 2: Applications and Technical Specifications of Advanced Microbiological Platforms

| Platform | Key Applications | Technical Basis | Detection Method | Sorting/Recovery Mechanism |

|---|---|---|---|---|

| Digital Plating (DP) | Single-cell isolation, AST, microbial interactions [1] | High-density picoliter microwell array with replaceable agar sheets [1] | Microscopic imaging | Agar sheet replacement for flexible microenvironment control [1] |

| AI-Powered Digital Colony Picker | Multi-modal phenotyping, strain sorting [3] | Addressable picoliter microchambers [3] | AI-driven image analysis | Laser-induced bubble technique [3] |

| Droplet Microfluidics | Enzyme screening, uncultivated microbe isolation [2] | Water-in-oil emulsion droplets [2] | Fluorescence detection | Dielectrophoretic sorting [4] |

| 3D-Printed Replica Plate | Antibacterial compound screening [5] | Mechanical colony transfer | Inhibition zone formation | Manual picking [5] |

The quantitative advantages of emerging platforms are particularly evident in time-sensitive applications such as clinical diagnostics and antibiotic susceptibility testing. The digital plating platform reduces the typical incubation time for Escherichia coli from 16-24 hours to just 6-7 hours, while enabling antibiotic susceptibility testing in under 6 hours [1]. This significant acceleration is attributed to microconfinement-enhanced metabolite accumulation and single-cell resolution analysis, which allow for earlier detection of growth and metabolic activity [1]. Similarly, droplet-based microfluidic systems have demonstrated pathogen detection within 5 hours with a detection limit of 50 CFU/mL, far surpassing traditional methods in speed and sensitivity [2].

Experimental Protocols for Advanced Microbial Analysis

Protocol 1: Digital Plating Platform for Single-Cell Isolation and AST

Principle: The digital plating (DP) platform integrates a high-density picoliter microwell array chip with a replaceable agar sheet, enabling digital quantification and phenotypic characterization at single-cell resolution [1].

Materials:

- PDMS PicoArray device (113,137 hexagonal microwells, 70 μm diagonal, 40 μm height) [1]

- Sylgard 184 silicone elastomer and curing agent (10:1, w/w) [1]

- LB broth powder and agar powder [1]

- Bacterial suspension (optimized concentration ~1×10⁶ cells/mL) [3]

- Appropriate reagents (antibiotics, metabolic indicators, dyes) [1]

Procedure:

- Device Preparation: Fabricate PDMS PicoArray device using conventional soft lithography with SU-8 3010 and 3050 negative photoresists to create channel and microwell layers [1].

- Agar Sheet Preparation: Dissolve LB broth (2.5 g) and agar (1.5 g) in 100 mL water and autoclave. Cool to 60°C and add appropriate reagents (antibiotics, dyes). Pour into sterilized PDMS chamber mold (76 mm × 26 mm × 1 mm), cover with plastic sheet, and solidify at room temperature [1].

- Bacterial Loading: Pre-degas the PicoArray device to create a vacuum. Introduce bacterial suspension (concentration optimized per Poisson distribution statistics) into the main channel, allowing partitioning into microwells via self-pumping mechanism [1] [3].

- Incubation: Cover the loaded microwell array with the prepared agar sheet. Incubate at appropriate temperature (e.g., 37°C for E. coli) for 6-7 hours [1].

- Analysis and Replacement: Image microwells using microscopy for quantification. For dynamic assays, replace agar sheet with different formulations (e.g., antibiotic-containing for AST) to flexibly regulate growth conditions [1].

Applications: This protocol enables single-cell isolation from mixed communities, rapid antibiotic susceptibility testing (<6 hours), and quantitative assessment of microbial interactions [1].

Protocol 2: AI-Powered Digital Colony Picking for Phenotypic Screening

Principle: The Digital Colony Picker (DCP) uses an addressable microfluidic chip with AI-driven image analysis to screen and export microbial clones based on multi-modal phenotypes at single-cell resolution [3].

Materials:

- Microfluidic chip (16,000 picoliter-scale microchambers) with PDMS mold layer, ITO metal film, and glass layer [3]

- Bacterial suspension (optimized for single-cell loading, ~1×10⁶ cells/mL) [3]

- Oil phase for droplet collection

- Collection plate (96-well format)

Procedure:

- Chip Loading: Pre-vacuum the microfluidic chip. Introduce bacterial suspension, allowing single cells to load into microchambers via vacuum-assisted distribution. Optimize cell concentration using Poisson distribution calculations (λ = 0.3) to maximize single-cell occupancy [3].

- Incubation: Place the loaded chip in a water-filled centrifuge tube to maintain humidity and prevent evaporation. Incubate at appropriate temperature until microscopic monoclones form [3].

- AI-Powered Identification: Inject oil phase into the chip. Use automated microscopy with AI-driven image recognition to identify microchambers containing monoclonal colonies with desired phenotypes [3].

- Laser-Induced Export: Position laser focus at the base of identified microchambers. Generate microbubbles via laser-induced bubble technique to propel single-clone droplets toward the outlet [3].

- Collection: Transfer exported clones to a 96-well collection plate using cross-surface microfluidic printing method [3].

Applications: High-throughput screening of microbial cell factories, identification of strains with improved metabolite production (e.g., lactate in Zymomonas mobilis), and functional gene discovery [3].

Protocol 3: Droplet Microfluidics for Filamentous Fungi Gene Knockout Screening

Principle: This method utilizes water-in-oil emulsion droplets to compartmentalize single fungal cells, enabling high-throughput screening based on growth phenotypes before visible colony formation [4].

Materials:

- Microfluidic droplet generation chip (T-junction or flow-focusing design) [2]

- Fusarium graminearum protoplast suspension

- Fungal culture medium (Tryptic Soy Broth)

- Surfactant-containing oil phase

- Calcofluor white fluorescent stain [4]

Procedure:

- Droplet Generation: Mix fungal protoplast suspension with culture medium and fluorescent stain. Inject through microfluidic droplet generator to create monodisperse water-in-oil emulsion droplets following Poisson distribution for single-cell encapsulation [4] [2].

- Incubation: Collect droplets and incubate at appropriate temperature for 24-48 hours. During incubation, mutant strains display distinct growth phenotypes (no growth vs. hyphae formation) detectable via fluorescent staining [4].

- Sorting: Analyze droplets using fluorescence detection to identify target phenotypes. Sort positive droplets using dielectrophoretic sorting or other microfluidic sorting techniques at throughput up to 28,000 droplets per hour [4].

- Recovery and Validation: Break sorted droplets to recover fungal cells. Plate on solid media for expansion and confirm gene knockout via PCR analysis [4].

Applications: High-throughput screening of filamentous fungi transformants, identification of gene knockout mutants, and isolation of strains with desired enzymatic activities [4].

The Scientist's Toolkit: Essential Research Reagent Solutions

Table 3: Key Research Reagents and Materials for Advanced Microbial Analysis

| Item | Function/Application | Example Specifications |

|---|---|---|

| PDMS PicoArray Device | High-density microwell array for single-cell compartmentalization | 113,137 hexagonal microwells; 70 μm diagonal, 40 μm height [1] |

| Replaceable Agar Sheets | Flexible microenvironment control for microbial growth | LB broth (2.5 g/100 mL) with agar (1.5 g/100 mL); customizable with nutrients/chemicals [1] |

| Microfluidic Chips with ITO Coating | Laser-induced bubble export of selected clones | 16,000 picoliter microchambers; ITO film transparency >86% [3] |

| Double-Ended Barcoded Primers | Multiplexed Nanopore sequencing for species identification | 40-bp barcodes flanking 16S rDNA primers (27F/1492R); enables pooling of thousands of samples [6] |

| Dual-Plasmid Biosensor System | Functional screening for metabolite production | Sensor plasmid + reporter plasmid; modular design for diverse metabolites [6] |

| TeSR 3D Media | hPSC expansion in 3D suspension culture | Fed-batch workflow; animal-origin free options available [7] |

The limitations of traditional plate culturing—particularly its labor-intensive workflows, prolonged incubation times, and limited single-cell resolution—present significant constraints for modern microbiology research and diagnostics. Digital plating platforms, microfluidic systems, and AI-powered technologies effectively address these challenges by enabling rapid, high-throughput microbial analysis with single-cell resolution. The protocols and methodologies detailed herein provide researchers with practical frameworks for implementing these advanced platforms, facilitating accelerated microbial detection, functional screening, and phenotypic characterization that surpass the capabilities of traditional approaches. As these technologies continue to evolve, they promise to further transform microbiological research, clinical diagnostics, and biotechnological applications through enhanced resolution, efficiency, and throughput.

The Digital Plating (DP) platform represents a significant advancement in microbial analysis, engineered to bridge the critical technological gap between conventional agar-based methods and modern high-throughput microfluidic systems. Traditional plate culturing, despite being the gold standard in microbiology laboratories, is notably hindered by labor-intensive workflows, prolonged incubation times (typically 18–72 hours), and limited single-cell resolution [1]. While robotic automation systems like the QPix Microbial Colony Pickers improve throughput for specific tasks, they do not fundamentally address the issue of long incubation times [8]. Conversely, droplet microfluidic technologies offer powerful single-cell analysis capabilities but introduce challenges such as droplet coalescence, difficulties in substance exchange, and complex operational setups that often require specialized expertise [1] [9].

The DP platform directly addresses these limitations by integrating the simplicity and practicality of traditional agar culturing with the precision and speed of digital bioassay technology [1]. Its core innovation lies in a high-density picoliter microwell array chip, combined with a unique replaceable agar sheet. This design allows bacterial suspensions to be partitioned into hundreds of thousands of micro-compartments via a self-pumping mechanism, followed by incubation under a nutrient- and chemical-laden agar cover [1] [10]. This hybrid architecture enables rapid microbial quantification within hours—demonstrated for Escherichia coli with a 6-7 hour detection time versus the 16-24 hours required by traditional methods—while also providing unparalleled flexibility for dynamic phenotypic screening and single-cell isolation from complex communities [1] [11]. By combining digital quantification with familiar agar-based workflows, the DP platform offers a scalable and cost-effective solution adaptable to clinical diagnostics, environmental microbiology, and synthetic biology research [1].

Key Components and Operational Principles

Core Hardware: The PicoArray Device

The foundation of the DP platform is the PicoArray device, a microfabricated chip containing a high-density array of picoliter-sized microwells. Typical devices feature 113,137 hexagonal microwells with specific dimensions of 70 μm (diagonal) by 40 μm in height [1]. The device is fabricated using conventional soft lithography with PDMS (polydysiloxane), a material chosen for its gas permeability, which is essential for the self-pumping mechanism. The design includes a main channel (52 mm length × 80 μm width × 60 μm height) and loading microchannels (17.9 mm length × 30 μm width × 20 μm height) that facilitate efficient sample distribution [1].

The Replaceable Agar Sheet

A defining feature of the DP platform is the replaceable agar sheet that serves as both the nutrient source and the physical cover for the microwell array. These sheets are typically prepared in standardized dimensions (76 mm × 26 mm × 1 mm) using a sterilized PDMS chamber mold [1]. The agar medium (e.g., LB broth with 1.5% agar) can be supplemented with various reagents—including antibiotics, specific metabolic indicators, or dyes—depending on experimental requirements. This replaceability enables researchers to flexibly alter the microenvironment within the picowells during an experiment, a capability not available in traditional solid-phase culturing or most microfluidic systems [1].

Self-Pumping Sample Loading Mechanism

The platform operates through a vacuum-assisted self-pumping mechanism that eliminates the need for external tubing or bulky pumping equipment. Prior to sample introduction, the PDMS PicoArray device undergoes pre-degassing to create a vacuum [1]. When a bacterial suspension is introduced at the inlet, this pre-established vacuum spontaneously draws the sample through the microchannel network, efficiently partitioning it into the individual microwells. This passive loading mechanism makes the system accessible to users without specialized microfluidics expertise [1].

Table: Core Components of the Digital Plating Platform

| Component | Description | Key Features |

|---|---|---|

| PicoArray Chip | PDMS-based microfluidic device with high-density microwell array | 113,137 hexagonal microwells; 70 μm diagonal × 40 μm height; fabricated via soft lithography [1] |

| Replaceable Agar Sheet | Thin, nutrient-infused solid medium sheet | Standardized dimensions (76 × 26 × 1 mm); customizable with antibiotics, indicators, or dyes [1] |

| Self-Pumping Mechanism | Vacuum-driven sample loading system | Pre-degassing induced vacuum; no external pumps or tubing required [1] |

The fundamental operational workflow begins with the introduction of a bacterial suspension into the pre-degassed PicoArray device. The vacuum-driven flow partitions individual bacterial cells into the microwells through statistical confinement. The device is then covered with the prepared agar sheet, which serves as a nutrient source while preventing evaporation. During incubation, metabolically active cells grow and form microcolonies within their individual compartments. The platform enables time-lapse monitoring of growth dynamics and phenotypic characteristics at single-cell resolution, followed by potential recovery of specific microcolonies for downstream analysis [1].

Application Protocols

Protocol 1: Rapid Bacterial Quantification and Viability Assessment

Purpose: To accurately quantify viable bacteria in a suspension within significantly reduced timeframes compared to traditional colony-forming unit (CFU) counts.

Materials and Reagents:

- PicoArray device (113,137 microwells)

- PDMS chamber mold for agar sheets

- LB broth powder (e.g., CM158)

- Agar powder (Biowest, Spain)

- Bacterial suspension (e.g., E. coli JM109)

- Normal saline for dilution

- Fluorescent viability stain (e.g., resazurin-based dyes), optional [1]

Procedure:

- Agar Sheet Preparation: Dissolve 2.5 g LB broth and 1.5 g agar in 100 mL distilled water. Autoclave the mixture and cool to 60°C. Pour into a sterilized PDMS chamber mold (76 mm × 26 mm × 1 mm), cover with a sterilized plastic sheet, and allow to solidify at room temperature [1].

- Sample Preparation: Dilute the stabilized bacterial culture in normal saline to achieve a target concentration of approximately 10⁵–10⁶ cells/mL. This dilution ensures optimal statistical distribution for single-cell occupancy in the microwells [1].

- Device Loading: Introduce 20–50 μL of the diluted bacterial suspension to the inlet of the pre-degassed PicoArray device. The self-pumping mechanism will spontaneously distribute the sample throughout the microwell array within minutes [1].

- Incubation and Imaging: Carefully place the prepared agar sheet onto the loaded PicoArray device. Incubate at 37°C while monitoring microcolony formation. For E. coli, positive microwells typically show detectable growth within 6–7 hours using brightfield or fluorescence microscopy [1].

- Quantification: Count the number of microwells containing microcolonies and calculate the original viable cell concentration using Poisson distribution statistics, adjusting for the number of wells and dilution factor [1].

Troubleshooting Tips:

- If loading is incomplete, ensure proper pre-degassing of the PDMS device.

- If evaporation occurs, verify the agar sheet is making complete contact with the chip surface.

- For slow-growing organisms, incubation times may be extended, though they typically remain shorter than conventional methods due to microconfinement effects [1].

Protocol 2: Rapid Antibiotic Susceptibility Testing (AST)

Purpose: To determine antibiotic susceptibility profiles of bacterial isolates in less than 6 hours, significantly faster than conventional AST methods.

Materials and Reagents:

- PicoArray device

- Agar sheets with and without antibiotics

- Mueller-Hinton broth or appropriate culture medium

- Antibiotic stock solutions (e.g., ampicillin sodium salt at 100 mg/mL)

- Test bacterial strain (e.g., Staphylococcus aureus ATCC 43300)

- Sterile 0.22-μm filters for antibiotic sterilization [1]

Procedure:

- Preparation of Antibiotic Agar Sheets: Prepare agar sheets as described in Protocol 1. Supplement with appropriate antibiotics at clinically relevant concentrations after cooling the autoclaved agar to 60°C. For example, prepare ampicillin-containing sheets at 32 μg/mL for Gram-negative bacteria [1].

- Sample Preparation: Dilute a fresh bacterial culture to approximately 10⁵ cells/mL in normal saline or appropriate buffer.

- Baseline Loading and Imaging: Load the bacterial suspension into a PicoArray device and cover with a non-supplemented agar sheet. Acquire baseline images to confirm initial cell distribution and viability [1].

- Antibiotic Exposure: After initial imaging (approximately 1-2 hours), carefully replace the non-supplemented agar sheet with an antibiotic-containing agar sheet. This replaceable agar feature enables dynamic alteration of growth conditions during the experiment [1].

- Monitoring and Analysis: Continue incubation at 35°C ± 2°C and monitor microcolony formation every 30-60 minutes. Compare growth rates between antibiotic-containing and control conditions. Susceptible strains will show significantly inhibited growth in antibiotic-containing wells within 3-4 hours [1].

- Interpretation: Determine the minimum inhibitory concentration (MIC) by testing a range of antibiotic concentrations and identifying the lowest concentration that prevents microcolony formation within the test period [1].

Protocol 3: Single-Cell Isolation from Mixed Microbial Communities

Purpose: To isolate and recover individual cells from complex microbial communities for pure culture establishment or rare cell screening.

Materials and Reagents:

- PicoArray device

- Selective and non-selective agar sheets

- Mixed microbial community sample (environmental, clinical, or synthetic)

- Differential media or metabolic indicators for target phenotypes

- Sterile recovery tools (micromanipulator or fine gauge needles) [1]

Procedure:

- Sample Preparation: Process the mixed community sample to achieve a single-cell suspension using appropriate dissociation techniques. Minimal dilution is required as the partitioning is statistical [1].

- Device Loading and Incubation: Load the sample into the PicoArray device and cover with a non-selective agar sheet to support the growth of diverse community members. Incubate for 6-12 hours while monitoring microcolony formation [1].

- Identification of Target Microcolonies: Using time-lapse imaging, identify microwells containing pure microcolonies derived from single cells. For specific phenotypes, the agar sheet can be replaced with one containing differential media or metabolic indicators (e.g., chromogenic substrates) to highlight specific metabolic capabilities [1].

- Recovery of Target Cells: Using a sterile micromanipulator or fine gauge needle, carefully excise the specific agar region above the target microwell and transfer to appropriate recovery media. Alternatively, the entire agar sheet can be carefully removed and the target microwell contents accessed directly from the array [1].

- Confirmation and Expansion: Streak the recovered cells onto conventional agar plates to confirm purity and establish stable cultures for downstream analysis [1].

Table: Performance Comparison: Digital Plating vs. Traditional Methods

| Parameter | Digital Plating Platform | Traditional Plate Culturing | Droplet Microfluidics |

|---|---|---|---|

| Incubation Time (E. coli) | 6–7 hours [1] | 16–24 hours [1] | Variable |

| Single-Cell Resolution | Yes [1] | Limited | Yes [1] |

| Environmental Control | High (replaceable agar) [1] | Low | Moderate |

| Throughput | ~100,000 microwells [1] | 100–300 CFU/plate | Very High [9] |

| Equipment Complexity | Moderate | Low | High [1] |

| Cell Recovery | Direct physical access [1] | Easy | Technically challenging [1] |

Essential Research Reagent Solutions

The successful implementation of Digital Plating protocols requires specific research reagents and materials optimized for the platform's unique architecture.

Table: Essential Research Reagent Solutions for Digital Plating

| Reagent/Material | Function | Application Notes |

|---|---|---|

| PDMS PicoArray Device | Microfabricated chip providing picoliter isolation chambers | 113,137 hexagonal wells; requires pre-degassing for self-pumping [1] |

| Agar Sheet Formulations | Nutrient delivery and environmental control | Customizable with antibiotics, indicators, dyes; 1.5% agar concentration optimal [1] |

| Viability Stains (Resazurin) | Fluorescent detection of metabolic activity | Enables rapid viability assessment; amplifies detection signal [10] |

| Antibiotic Stock Solutions | AST and selective enrichment | Prepare at high concentration (e.g., 100 mg/mL); filter sterilize [1] |

| Differential Media Components | Phenotypic screening and identification | Chromogenic substrates, pH indicators, specific metabolic supplements |

| Biosensor Strains | Detection of specific metabolites or interactions | Engineered reporter strains for monitoring microbial interactions [9] |

The Digital Plating platform establishes a new paradigm in microbial analysis by successfully integrating the practical benefits of traditional agar-based methodologies with the precision and throughput of digital single-cell analysis. Its capacity for rapid quantification (6-7 hours for E. coli), flexible phenotypic screening through replaceable agar sheets, and efficient single-cell isolation addresses multiple limitations inherent in both conventional culture methods and existing microfluidic systems [1]. The platform's demonstrated applications in antibiotic susceptibility testing, microbial interaction studies, and selective enrichment from complex communities position it as a versatile tool for advancing research in clinical diagnostics, drug discovery, environmental microbiology, and synthetic biology [1] [9].

As the field continues to confront challenges such as antimicrobial resistance and the need to access microbial dark matter, the DP platform's unique combination of familiarity, flexibility, and high-resolution capabilities offers a practical pathway for enhancing research efficiency and expanding our fundamental understanding of microbial life. Its compatibility with standard laboratory workflows and minimal requirement for specialized expertise further lower adoption barriers, suggesting strong potential for widespread implementation across diverse microbiological research contexts.

The digital plating (DP) platform represents a transformative approach in microbial analysis, integrating the principles of traditional plate culturing with cutting-edge digital bioassay technology [1]. This platform addresses critical limitations of conventional methods, which are often hindered by labor-intensive workflows, prolonged incubation times (typically 18-72 hours), and limited single-cell resolution [1] [11]. At the heart of this system are two core components: a high-density picoliter microwell array chip and a replaceable agar sheet [1]. This combination enables rapid isolation, quantification, and phenotypic characterization of microorganisms, achieving precise bacterial quantification within hours—significantly faster than conventional plate culturing (e.g., 6-7 hours for Escherichia coli versus 16-24 hours with traditional methods) [1]. The platform's versatility extends to single-cell isolation from mixed communities, selective enrichment using differential media, rapid antibiotic susceptibility testing (<6 hours), and quantitative assessment of microbial interactions [1], making it particularly valuable for researchers, scientists, and drug development professionals engaged in high-throughput microbial analysis.

Technical Specifications of Core Components

High-Density Picoliter Microwell Array

The microwell array serves as the foundational element of the DP platform, enabling digital single-cell compartmentalization. The specific PicoArray device documented in recent literature contains an array of 113,137 hexagonal microwells fabricated using conventional soft lithography with polydimethylsiloxane (PDMS) [1].

Table 1: Physical Specifications of the PicoArray Microwell Chip

| Parameter | Specification | Functional Significance |

|---|---|---|

| Total Microwell Count | 113,137 wells | Enables high-throughput single-cell analysis |

| Microwell Geometry | Hexagonal | Optimal space-filling arrangement for efficient partitioning |

| Microwell Dimensions | 70 μm (diagonal) × 40 μm (height) | Confines bacterial growth within picoliter volumes |

| Channel System | Main channel: 52 mm × 80 μm × 60 μm; Loading microchannel: 17.9 mm × 30 μm × 20 μm | Facilitates sample loading via self-pumping mechanism |

This high-density configuration allows the partitioning of bacterial suspensions into numerous picoliter-scale compartments via a pre-degassing-induced vacuum [1]. The small volume of each microwell enhances metabolite accumulation, significantly accelerating microbial detection to ≤8 hours—a key advantage over traditional culture methods [1].

Replaceable Agar Sheets

The second revolutionary component is the replaceable agar-based solid medium sheet that covers the microwell array. These sheets are prepared by dissolving LB broth powder and agar powder in water, autoclaving the mixture, adding specific reagents depending on experimental purposes (e.g., dyes, antibiotics, metabolic indicators), and pouring it into a sterilized PDMS chamber mold (76 mm × 26 mm × 1 mm) [1]. After solidification at room temperature, the resulting agar sheet serves as a replaceable nutrient source and chemical delivery system [1].

The replaceability of the agar cover is the platform's most innovative feature, allowing dynamic control and flexible regulation of microbial growth conditions through agar replacement [1]. This functionality enables researchers to perform complex experimental sequences without disturbing the partitioned cells in the microwell array, facilitating applications from precise selection of individuals with desired properties to rapid antibiotic susceptibility testing [1].

Operational Workflow

The integrated operation of these core components follows a systematic workflow that transforms traditional microbial cultivation into a digital assay format.

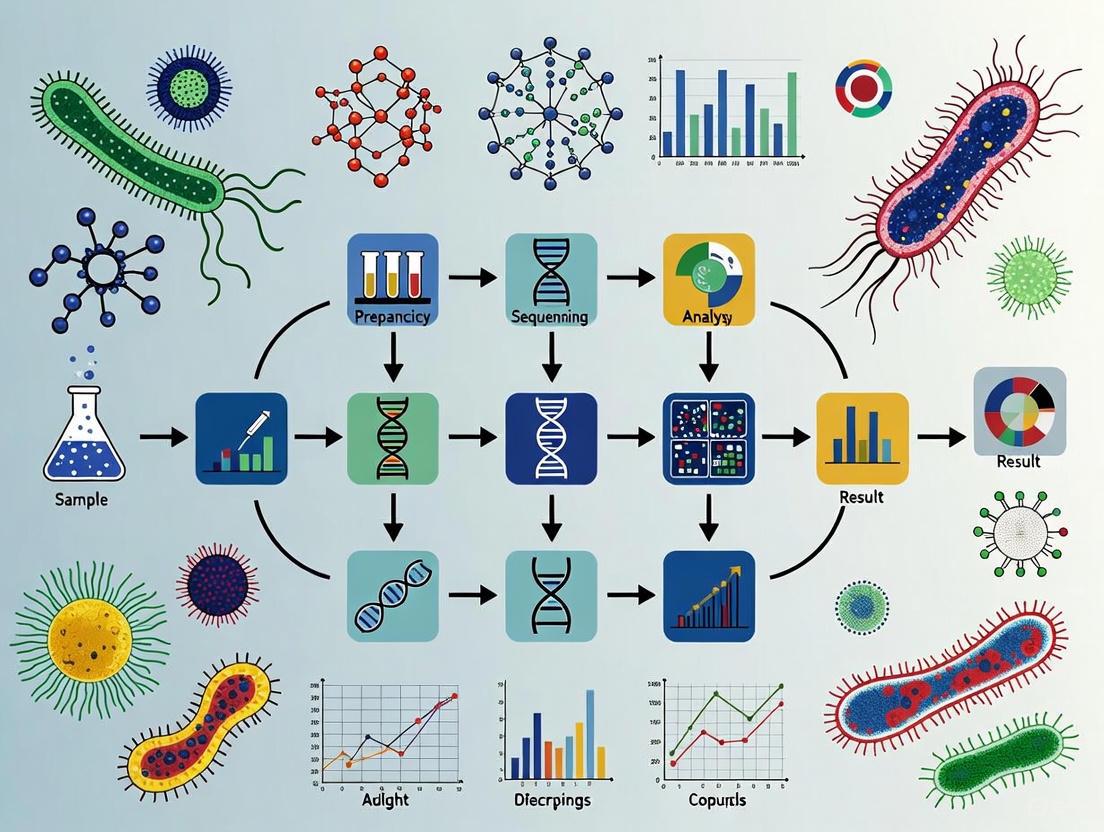

Diagram 1: Digital plating workflow showing core process with key innovations.

The process begins with introducing a bacterial suspension into the PicoArray device, where it partitions into individual microwells via a self-priming mechanism that requires no external pumps [1]. The partitioned sample is then covered with a specific nutrient- or chemical-laden agar sheet for incubation [1]. Thanks to the replaceability of the agar cover, the microenvironment within the picowells can be flexibly altered for culturing or screening microbes, significantly extending the application range beyond static cultivation systems [1]. This capability enables complex multi-stage experiments where different growth conditions, selective pressures, or chemical stimuli can be introduced sequentially without disrupting the individually compartmentalized cells.

Research Reagent Solutions

Table 2: Essential Research Reagents for Digital Plating Platform

| Reagent/Material | Function | Example Specifications |

|---|---|---|

| PDMS Prepolymer | Device fabrication | Sylgard 184 silicone elastomer with curing agent (10:1 w/w) |

| Agar Powder | Solid matrix for replaceable sheets | Biowest, Spain |

| LB Broth Powder | Nutrient base for microbial growth | CM158, Beijing Land Bridge Technology, China |

| Antibiotics | Selective pressure for phenotypic screening | Ampicillin sodium salt (100 mg/mL stock solution) |

| Fluorescent Dyes | Cell viability assessment and metabolic indicators | Concentration varies by experimental design |

| Bacterial Strains | Experimental subjects | E. coli JM109, GFP-tagged E. coli BL21, S. aureus ATCC 43300, Salmonella enterica 14028 |

Detailed Experimental Protocols

Protocol 1: Platform Setup and Basic Microbial Quantification

Objective: To isolate and quantify bacterial populations at single-cell resolution using the digital plating platform.

Materials:

- PicoArray device (113,137 hexagonal microwells)

- Sterilized PDMS chamber mold (76 mm × 26 mm × 1 mm)

- LB broth powder (2.5 g/1000 mL) and agar powder (1.5 g/1000 mL)

- Bacterial suspension (e.g., E. coli JM109) in normal saline

- Autoclave, sterile containers, and weighing instruments

Procedure:

- Agar Sheet Preparation:

- Dissolve 2.5 g LB broth powder and 1.5 g agar powder in 1000 mL distilled water

- Autoclave the mixture and cool to 60°C

- Pour into sterilized PDMS chamber mold and cover with sterilized plastic sheet

- Place a glass slide and weight on the plastic sheet for even thickness

- After solidification at room temperature, remove the mold to obtain agar sheet [1]

Sample Loading:

- Introduce bacterial suspension into the PicoArray device

- Allow self-priming vacuum to partition sample into microwells [1]

Incubation and Analysis:

- Cover the partitioned sample with the prepared agar sheet

- Incubate at appropriate temperature (37°C for E. coli)

- Monitor microbial growth for 6-7 hours [1]

- Image the array using fluorescence microscopy or scanner

- Quantify positive wells based on metabolic activity or fluorescence

Protocol 2: Rapid Antibiotic Susceptibility Testing (AST)

Objective: To determine antibiotic susceptibility in less than 6 hours using replaceable agar sheets.

Materials:

- Prepared PicoArray with partitioned bacterial suspension

- Agar sheets containing gradient concentrations of antibiotics (e.g., ampicillin)

- Control agar sheets without antibiotics

Procedure:

- Initial Cultivation:

- Cover partitioned bacterial sample with nutrient agar sheet (without antibiotics)

- Incubate for 2-3 hours to establish initial growth [1]

Antibiotic Exposure:

- Replace initial agar sheet with antibiotic-laden agar sheet

- Ensure complete contact with microwell array

- Incubate for 3 hours [1]

Assessment and Analysis:

- Compare growth in antibiotic-containing wells to control wells

- Determine minimum inhibitory concentration (MIC) based on growth inhibition

- Calculate susceptibility based on the fraction of wells showing continued growth

The replaceable agar sheet technology enables this multi-stage assay without disturbing the partitioned cells, providing susceptibility results in <6 hours compared to 16-24 hours with traditional methods [1].

Diagram 2: Rapid antibiotic susceptibility testing workflow comparison.

Applications in High-Throughput Microbial Analysis

The integration of high-density microwell arrays with replaceable agar sheets enables diverse applications that leverage their unique capabilities:

Single-Cell Isolation from Mixed Communities: The platform's partitioning efficiency enables isolation of individual cells from complex samples without prior dilution, overcoming interspecies competition that plagues traditional plating [1].

Selective Enrichment Using Differential Media: The replaceable agar system allows sequential application of different selective media to the same partitioned population, enabling sophisticated screening protocols [1].

Quantitative Microbial Interaction Studies: The ability to control microenvironment conditions while monitoring individual wells facilitates investigation of microbial interactions through metabolite exchange or signaling molecules [1].

Cultivation of Previously Unculturable Microbes: By recreating specific microenvironments through agar composition and avoiding competition, the platform shows promise for accessing microbial "dark matter" [12].

The synergistic combination of high-density picoliter microwell arrays and replaceable agar sheets in the digital plating platform represents a significant advancement in microbial analysis methodology. This integration bridges the gap between high-throughput microfluidics and practical laboratory routines, offering researchers a scalable, cost-effective solution that maintains the familiarity of agar-based culturing while providing digital single-cell resolution [1]. The platform's flexibility, accelerated timeline, and compatibility with diverse experimental designs position it as a powerful tool for advancing research in clinical diagnostics, environmental microbiology, synthetic biology, and drug development. By transforming traditional plating into a digital, programmable format, these core components enable a new generation of microbial studies that leverage single-cell resolution and dynamic environmental control.

The self-pumping mechanism represents a pivotal innovation within the digital plating (DP) platform, enabling the automated partitioning of bacterial suspensions into high-density picoliter microwell arrays without the need for external tubing, connections, or bulky pumping equipment [1]. This mechanism leverages a pre-degassing-induced vacuum to drive the rapid and spontaneous partitioning of samples, making the platform particularly accessible to non-microfluidics experts and smaller laboratories [1]. By replacing complex fluidic operations with a simple, self-contained process, this technology bridges the gap between high-throughput microfluidics and practical laboratory routines, facilitating robust and versatile microbial detection and analysis [1].

Principle of Operation

The core principle underlying the self-pumping mechanism is the creation of a vacuum via the pre-degassing of the polydimethylsiloxane (PDMS) material used to fabric the PicoArray device [1]. When the PDMS device is degassed prior to use, air is evacuated from its porous microstructure. Upon contact with a liquid bacterial suspension, the stored vacuum energy creates a pressure differential that spontaneously draws the sample into the device's network of microchannels and microwells. This capillary-driven flow continues until all microwells are filled, achieving complete partitioning of the sample into discrete picoliter-volume compartments without any external power source or fluidic controls.

Key Specifications and Performance Metrics

The following table summarizes the critical specifications of the PicoArray device and the performance characteristics of its self-pumping mechanism:

Table 1: Technical Specifications of the PicoArray Device and Self-Pumping Mechanism

| Parameter | Specification | Experimental Context |

|---|---|---|

| Microwell Array Density | 113,137 microwells per chip | Fabricated using conventional soft lithography [1] |

| Individual Microwell Volume | Picoliter scale | Enables single-cell confinement [1] |

| Microwell Geometry | Hexagonal | Diagonal: 70 μm; Height: 40 μm [1] |

| Microchannel Dimensions | Loading channel: 30 μm width, 20 μm height [1] | Facilitates fluid distribution |

| Quantification Time | 6-7 hours for E. coli [1] | Significant reduction from conventional methods (16-24 hours) [1] |

| Antibiotic Susceptibility Testing (AST) Time | <6 hours [1] | Enabled by rapid metabolite accumulation in microconfinement |

Detailed Experimental Protocol

This section provides a step-by-step protocol for utilizing the self-pumping mechanism for microbial analysis.

Materials and Reagents

Table 2: Essential Research Reagent Solutions and Materials

| Item | Function/Description | Example/Specification |

|---|---|---|

| PDMS PicoArray Device | Self-pumping chip containing the microwell array | Fabricated from Sylgard 184 silicone elastomer [1] |

| Bacterial Suspension | Sample for analysis | Prepared in normal saline to desired concentration [1] |

| Agar Solid Medium Sheet | Nutrient source for microbial growth | Contains LB broth (2.5 g/L) and agar (1.5 g/L) [1] |

| LB Broth Powder | Base nutrient component for culture medium | Example: CM158 from Beijing Land Bridge Technology [1] |

| Agar Powder | Gelling agent for solid medium sheet | Example: Biowest, Spain [1] |

| Specific Reagents | For selective enrichment or screening | Dyes, antibiotics, or metabolic indicators added to cooled agar [1] |

Step-by-Step Procedure

Step 1: Device Preparation and Pre-degassing

- Fabricate the PicoArray device using conventional soft lithography with SU-8 negative photoresists on silicon wafers to create molds for the channel and microwell layers [1].

- Prepare the PDMS prepolymer by thoroughly mixing the silicone elastomer and curing agent (10:1, w/w), then pour onto the SU-8 molds [1].

- Cure the PDMS at 90°C for 1 hour, then peel the slabs from the molds [1].

- Prior to the experiment, degas the PDMS PicoArray device to create the internal vacuum that will power the self-pumping action [1].

Step 2: Preparation of Covering Agar Sheet

- Prepare a sterile agar solution by dissolving LB broth powder (2.5 g) and agar powder (1.5 g) in 100 mL of water, followed by autoclaving [1].

- Cool the autoclaved agar solution to approximately 60°C [1].

- As needed, add specific reagents such as antibiotics, dyes, or metabolic indicators to the agar solution and mix thoroughly [1].

- Pour the mixture into a sterilized PDMS chamber mold (76 mm × 26 mm × 1 mm), cover with a sterilized plastic sheet, and place a glass slide with a weight on top [1].

- Allow the agar to solidify at room temperature, then remove the mold to obtain a uniform agar solid media sheet [1].

Step 3: Sample Loading and Partitioning

- Dilute the bacterial subculture with normal saline to achieve the desired concentration for analysis [1].

- Introduce the prepared bacterial suspension to the inlet port of the pre-degassed PicoArray device [1].

- Observe as the self-pumping mechanism spontaneously draws the suspension into the microchannel network and partitions it into the high-density picoliter microwell array via the pre-degassing-induced vacuum [1].

- Ensure complete filling by verifying that all target microwells contain the suspension.

Step 4: Incubation and Analysis

- Carefully cover the filled PicoArray with the prepared agar solid medium sheet, ensuring full contact to facilitate nutrient diffusion into the microwells [1].

- Place the assembled platform in an appropriate incubator (e.g., 37°C for E. coli) for the required duration [1].

- Monitor microbial growth, quantification, or phenotypic responses using appropriate microscopy or imaging systems at regular intervals.

- For multi-stage assays, leverage the replaceability of the agar cover to dynamically alter growth conditions by replacing with a new sheet containing different chemical inducers or antibiotics [1].

Workflow Visualization

Figure 1: Workflow of the self-pumping digital plating platform, illustrating the automated partitioning process and flexible assay design enabled by the replaceable agar sheet.

Applications Enabled by the Self-Pumping Mechanism

The efficiency and simplicity of the self-pumping mechanism facilitate several advanced applications within the digital plating platform [1]:

- Single-Cell Isolation from Mixed Communities: The precise partitioning enables the isolation and clonal cultivation of individual bacteria from complex samples without the need for prior dilution.

- Rapid Antibiotic Susceptibility Testing (AST): The microconfinement effect accelerates bacterial responses, allowing for AST results in less than 6 hours.

- Selective Enrichment and Screening: The replaceable agar sheet system permits dynamic changes to the chemical microenvironment, enabling flexible phenotypic screening.

- Quantitative Assessment of Microbial Interactions: The platform supports the study of interactions between different microbial species at the single-cell level.

The digital plating (DP) platform represents a transformative advancement in microbial analysis, integrating the established principles of traditional plate culturing with cutting-edge digital bioassay technology [1]. This hybrid system addresses critical limitations of conventional methods by enabling rapid isolation, precise quantification, and comprehensive phenotypic characterization of microorganisms at the single-cell level [1]. The core of the DP platform consists of a high-density picoliter microwell array chip that partitions bacterial suspensions via a self-pumping mechanism, after which the chip is covered with a replaceable nutrient- or chemical-laden agar sheet for incubation and analysis [1]. This innovative approach bridges the gap between high-throughput microfluidics and practical laboratory workflows, offering a scalable and cost-effective solution for clinical diagnostics, environmental microbiology, and synthetic biology applications where single-cell resolution is critical [1].

Table 1: Performance Comparison: Digital Plating vs. Traditional Methods

| Parameter | Digital Plating Platform | Traditional Plate Culturing |

|---|---|---|

| Incubation Time (E. coli) | 6-7 hours [1] | 16-24 hours [1] |

| Antibiotic Susceptibility Testing | <6 hours [1] | Typically 18-24 hours or longer |

| Single-Cell Isolation | Precise isolation from mixed communities [1] | Limited by dilution and spreading techniques |

| Quantification Resolution | Digital quantification at single-cell level [1] | Colony-forming unit counting |

| Environmental Flexibility | Dynamic microenvironment control via replaceable agar sheets [1] | Fixed medium conditions |

| Throughput Capability | High-density picoliter microwell arrays (e.g., 113,137 wells) [1] | Limited by plate surface area |

Speed and Efficiency Advantages

Accelerated Microbial Detection and Analysis

The DP platform significantly reduces microbial detection times through microconfinement-enhanced metabolite accumulation within picoliter-scale microwells [1]. This confined environment accelerates microbial growth and metabolic activity, enabling precise bacterial quantification within hours rather than days [1]. For Escherichia coli, the DP platform reduces detection time to 6-7 hours compared to 16-24 hours required for traditional plate culturing methods [1]. This remarkable acceleration stems from the physical partitioning of individual cells into microwells, where localized accumulation of metabolic products creates favorable growth conditions that support rapid proliferation detectable within significantly shortened timeframes [1].

Rapid Antibiotic Susceptibility Testing

The platform enables particularly rapid antibiotic susceptibility testing (AST), completing analyses in less than 6 hours compared to the 18-24 hours typically required by conventional methods [1]. This expedited timeline is achieved through single-cell resolution monitoring of phenotypic responses to antimicrobial agents within the microwell array [1]. The replaceable agar sheet functionality allows introduction of antibiotics at precise concentrations after initial cell loading and partitioning, enabling researchers to observe bacterial responses to antimicrobial challenge in real-time without the need for subculturing or manual intervention [1]. This capability has profound implications for clinical diagnostics, where rapid AST results can directly impact patient treatment outcomes and antimicrobial stewardship efforts.

Advanced Quantification Capabilities

Digital Quantification Methodology

The DP platform employs digital quantification principles similar to digital PCR, where statistical analysis of positive microwells enables precise enumeration of viable microorganisms [1]. Each microwell in the high-density array (typically containing 113,137 hexagonal microwells) functions as a miniature cultivation chamber [1]. Following partitioning and incubation, microwells containing proliferated microorganisms are identified and counted, allowing for absolute quantification of the initial inoculum through Poisson distribution statistics [1]. This approach provides superior accuracy compared to traditional colony-forming unit (CFU) counting, especially at low bacterial concentrations where conventional methods suffer from significant statistical uncertainty.

Enhanced Resolution for Complex Communities

Unlike traditional plating that obscures rare or slow-growing taxa through interspecies competition, the physical separation afforded by the microwell array enables resolution of individual cells from mixed microbial communities without prior dilution [1]. This capability allows researchers to identify and characterize minority populations that would otherwise be overwhelmed by dominant species in conventional culture systems [1]. The platform's compartmentalization prevents competitive exclusion and enables quantitative assessment of microbial interactions, including synergism and antagonism between different species or strains [1]. This makes the DP platform particularly valuable for studying complex environmental samples or clinical specimens containing polymicrobial communities.

Phenotypic Characterization at Single-Cell Resolution

High-Content Screening Capabilities

The DP platform enables comprehensive phenotypic characterization through its unique ability to monitor individual cells across multiple parameters and conditions [1]. The replaceable agar sheet functionality allows dynamic modification of the microenvironment during experiments, facilitating flexible phenotypic screening approaches [1]. Researchers can initially culture microorganisms under standard conditions, then replace the agar sheet with media containing specific compounds, antibiotics, or metabolic indicators to assess phenotypic responses at the single-cell level [1]. This capability enables high-content screening for traits including antibiotic susceptibility, metabolic capabilities, and stress responses while maintaining spatial registration of individual cells throughout sequential manipulations.

Single-Cell Isolation and Clonal Cultivation

A key advantage of the DP platform is its ability to precisely isolate individual cells from complex samples for subsequent clonal cultivation and analysis [1]. The microwell array effectively partitions single cells from mixed microbial communities without the need for prior dilution or sophisticated instrumentation [1]. Once identified, specific cells of interest can be recovered from individual microwells for downstream applications including whole-genome sequencing, further phenotypic characterization, or strain development [1]. This functionality bridges the gap between cultivation-based and molecular approaches, enabling researchers to correlate genomic information with phenotypic traits observed at the single-cell level.

Table 2: Application Range of the Digital Plating Platform

| Application | Methodology | Key Advantage |

|---|---|---|

| Single-Cell Isolation | Partitioning of mixed communities into picoliter wells | Isolation without competitive exclusion [1] |

| Selective Enrichment | Use of differential media in agar sheets | Flexible medium switching during experiments [1] |

| Antibiotic Susceptibility Testing | Monitoring response to antibiotics in agar cover | Results in <6 hours [1] |

| Microbial Interaction Studies | Co-partitioning of multiple species in wells | Quantitative assessment of interactions [1] |

| Phenotypic Heterogeneity | Time-lapse monitoring of individual wells | Resolution of subpopulation differences [1] |

Experimental Protocols

Protocol 1: Fabrication of PicoArray Devices

Materials: PDMS prepolymer (Sylgard 184), curing agent, SU-8 3010 and 3050 negative photoresists, silicon wafers, punching tool.

Methodology:

- Create SU-8 molds for channel layer (52mm length × 80μm width × 60μm height) and microwell layer using conventional soft lithography [1].

- Prepare PDMS prepolymer by thoroughly mixing silicone elastomer and curing agent (10:1, w/w) and degassing.

- Pour degassed PDMS onto SU-8 molds and cure at 90°C for 1 hour.

- Carefully peel cured PDMS slabs from molds and create inlet port on channel layer with punching tool.

- Align PDMS channel layer and microwell layer face-to-face to form reversible seal [1].

Technical Notes: Typical microwell dimensions are 70μm (diagonal) × 40μm (height), with arrays containing up to 113,137 hexagonal microwells [1]. The reversible sealing allows retrieval of specific cells after analysis.

Protocol 2: Preparation of Covering Agar Solid Media Sheets

Materials: LB broth powder, agar powder, autoclave, PDMS chamber mold (76mm × 26mm × 1mm), sterile plastic sheet, reagents for experimental purposes (dyes, antibiotics, metabolic indicators).

Methodology:

- Dissolve 2.5g LB broth powder and 1.5g agar powder in 1000mL water and autoclave.

- Cool agar solution to 60°C and add appropriate reagents (e.g., antibiotics, metabolic indicators) depending on experimental goals.

- Pour mixture into sterilized PDMS chamber mold and cover with sterilized plastic sheet.

- Place glass slide and weight onto plastic sheet to ensure uniform thickness.

- Allow solidification at room temperature before removing PDMS chamber mold [1].

Technical Notes: The replaceable agar sheet is fundamental to the platform's flexibility. Multiple sheets with different compositions can be sequentially applied to the same microwell array to study microbial responses to changing conditions.

Protocol 3: Rapid Antibiotic Susceptibility Testing

Materials: Prepared PicoArray device, bacterial suspension, antibiotic-containing agar sheets, ampicillin sodium salt (or other antibiotics), normal saline.

Methodology:

- Prepare bacterial suspension by diluting subculture solution with normal saline to desired concentration.

- Load bacterial suspension into PicoArray device via self-pumping mechanism driven by pre-degassing-induced vacuum [1].

- Cover loaded device with antibiotic-containing agar sheet (e.g., ampicillin at appropriate concentration).

- Incubate and monitor periodically for growth inhibition.

- Analyze results within 6 hours by quantifying viable cells in antibiotic-containing versus control conditions [1].

Technical Notes: For ampicillin testing, prepare stock solution at 100mg/mL in distilled water and sterilize by filtration through 0.22μm sterile filter [1]. The platform's single-cell resolution enables detection of heteroresistance and persistence at frequencies undetectable by conventional methods.

Research Reagent Solutions

Table 3: Essential Research Reagents for Digital Plating Applications

| Reagent/Material | Function | Example Specifications |

|---|---|---|

| PDMS (Sylgard 184) | Device fabrication | Silicone elastomer basecuring agent (10:1 w/w) [1] |

| SU-8 Photoresist | Mold creation | SU-8 3010, 3050 for features [1] |

| Agar Powder | Solid matrix for covers | Biowest or equivalent, 1.5g/L [1] |

| LB Broth | Nutrient base | 2.5g/L in agar sheets [1] |

| Ampicillin Sodium | Antibiotic testing | Stock: 100mg/mL, 0.22μm filtered [1] |

| Fluorescent Dyes | Cell labeling & viability | SYTOX Green, Hoechst 33342 [13] |

| OPP (O-propargyl-puromycin) | Translation monitoring | Puromycin analog for biosynthesis tracking [13] |

Figure 1: Digital Plating Experimental Workflow

Figure 2: Technology Comparison Overview

From Theory to Bench: Practical Applications and Workflows in Drug Discovery and Diagnostics

The digital plating (DP) platform represents a significant advancement in microbial analysis, merging the principles of traditional agar-based culturing with the precision of digital microfluidics. This platform centers on a high-density picoliter microwell array chip (PicoArray) used in conjunction with a replaceable agar sheet [1] [11]. The core innovation lies in its ability to partition a bacterial suspension into thousands of isolated picoliter-scale compartments via a self-pumping mechanism, followed by incubation under a solid agar medium sheet. This system enables rapid microbial quantification and phenotypic characterization within hours, a substantial improvement over the 16-24 hours required for traditional methods [1]. The replaceable agar sheet provides remarkable flexibility, allowing researchers to dynamically alter the microbial growth microenvironment for applications ranging from antibiotic susceptibility testing to the isolation of specific microbes from complex communities [1]. This protocol details the fabrication of the PicoArray device and the preparation of the essential agar sheets, providing researchers with the tools to implement this cutting-edge technology in high-throughput microbial analysis and drug development workflows.

Fabrication of PicoArray Devices

The PicoArray device serves as the foundation of the digital plating platform, providing the microstructure for isolating and analyzing individual microbial cells. Below are detailed protocols for fabricating devices using two different material systems.

Silicon-Glass Based PicoArray Fabrication

This method produces a highly durable device through silicon-glass anodic bonding [14].

- Materials: Silicon wafer (Si(100)), Corning 7740 glass wafer, photoresist (PR 1813, PR 1827, AZ9260), buffered HF, reactive ion etching mask (thermal oxide layer).

- Equipment: Deep reactive ion etching system (STS), spin coater, photolithography setup, wafer bonder (EV500, EV Group), RCA cleaning setup.

Procedure:

- Thermal Oxidation: Grow a 0.6 μm thermal oxide layer on a silicon wafer to serve as a reactive ion etching mask.

- Pico-Reaction Chamber Patterning:

- Spin-coat PR 1813 photoresist onto the oxidized silicon wafer.

- Transfer the pico-reaction chamber pattern via photolithography and etch the thermal oxide layer with buffered HF.

- Remove photoresist with a stripper (PRS 2000).

- Microchannel Patterning:

- Apply a new layer of PR 1827 photoresist.

- Transfer the microchannel pattern via photolithography and reactive ion etching.

- Perform deep reactive ion etching to obtain ~135 μm deep microchannels.

- Strip the photoresist.

- Final Etching and Through-Hole Creation:

- Re-etch the wafer using the deep RIE system to achieve the final depths: ~15 μm for reaction chambers and ~150 μm for microchannels.

- Apply AZ9260 photoresist to the wafer's backside.

- Transfer the inlet/outlet hole pattern via photolithography and etch through-holes.

- Surface Preparation and Bonding:

- Clean the wafer using RCA treatment.

- Grow a 0.2 μm thermal silicon oxide layer on the surface to enable subsequent functionalization for chemical reactions.

- Anodically bond the microfabricated silicon wafer to the glass wafer at 400°C and 1000 V.

The final device contains an array of 1,278 individual pico-reaction chambers [14]. Each three-dimensional chamber measures 90 μm wide, 200 μm long, and 15 μm deep, yielding an internal volume of 270 picoliters and a reactive interior surface area of 0.045 mm² [14]. The fluid channels are designed with a tapered shape based on fluid mechanical modeling to ensure a uniform flow rate across all reaction chambers [14].

PDMS-Based PicoArray Fabrication

This method utilizes soft lithography for rapid prototyping and produces a device containing 113,137 hexagonal microwells [1].

- Materials: PDMS prepolymer (Sylgard 184 silicone elastomer and curing agent), SU-8 3010 and SU-8 3050 negative photoresists, silicon wafers.

- Equipment: Plasma cleaner, oven, photolithography setup, punching tool.

Procedure:

- Mold Fabrication:

- Pattern SU-8 3010 and SU-8 3050 negative photoresists on separate silicon wafers to create two molds: one for the channel layer (main channel: 52 mm L × 80 μm W × 60 μm H) and one for the microwell layer (microwell: 70 μm diagonal × 40 μm H; loading microchannel: 17.9 mm L × 30 μm W × 20 μm H) [1].

- PDMS Molding:

- Thoroughly degas a PDMS prepolymer mixture (elastomer:curing agent = 10:1 w/w).

- Pour the prepolymer onto the SU-8 molds.

- Cure at 90°C for 1 hour.

- Carefully peel off the molded PDMS slabs from the molds.

- Device Assembly:

- Create an inlet port on the PDMS channel layer with a punching tool.

- Align the PDMS channel layer and the PDMS microwell layer face-to-face and bring them into conformal contact to form a reversible seal.

Table 1: Specifications and Comparison of PicoArray Fabrication Methods

| Parameter | Silicon-Glass Device [14] | PDMS Device [1] |

|---|---|---|

| Base Material | Silicon substrate anodically bonded to glass | Polydimethylsiloxane (PDMS) |

| Fabrication Method | Standard microelectronic fabrication & anodic bonding | Soft lithography & reversible bonding |

| Total Number of Wells | 1,278 | 113,137 |

| Individual Well Volume | 270 picoliters | Picoliter-scale (precise volume not specified) |

| Well Geometry | Rectangular (90 μm wide × 200 μm long × 15 μm deep) | Hexagonal (70 μm diagonal × 40 μm height) |

| Key Advantage | High durability; integrated fluidic channels | Rapid prototyping; higher well density; lower cost |

PicoArray Fabrication Paths

Preparation of Covering Agar Solid Media Sheets

The agar sheet is a critical component of the DP platform, acting as a replaceable nutrient source and enabling dynamic manipulation of the microbial growth environment.

- Materials: LB broth powder, agar powder, sterile distilled water, antibiotic stocks (e.g., Ampicillin sodium salt), specific metabolic indicators or dyes as needed.

- Equipment: Autoclave, water bath, sterile PDMS chamber mold (76 mm × 26 mm × 1 mm), sterilized plastic sheet, glass slide, weight.

Procedure:

- Prepare Agar Solution:

- Dissolve 2.5 g of LB broth powder and 1.5 g of agar powder in 100 mL of distilled water [1]. This creates a standard LB agar mixture at 1.5% agar.

- For antibiotic plates, refer to Table 2 for recommended stock and working concentrations.

- Sterilize:

- Cool and Additives:

- Cool the sterile molten agar to approximately 60°C in a water bath [15] [1]. This temperature keeps the agar liquid but prevents thermal degradation of most antibiotics.

- If adding antibiotics, dyes, or other chemical inducers, mix them thoroughly into the agar solution at this stage. Ensure antibiotic stocks are filter-sterilized.

- Cast Agar Sheets:

- Pour the mixture into a sterilized PDMS chamber mold with internal dimensions of 76 mm × 26 mm × 1 mm [1].

- Cover the mold with a sterilized plastic sheet.

- Place a glass slide and a weight on top of the plastic sheet to ensure a uniform thickness and flat surface.

- Solidify:

- Allow the agar to solidify at room temperature.

- Once solid, carefully remove the PDMS chamber mold to obtain the final agar solid media sheet, ready for use.

Table 2: Common Antibiotic Stock and Working Concentrations for Agar Plates [15]

| Antibiotic | Recommended Stock Concentration | Recommended Working Concentration | Solvent |

|---|---|---|---|

| Ampicillin | 100 mg/mL | 100 µg/mL | Water |

| Carbenicillin | 100 mg/mL | 100 µg/mL | Water |

| Chloramphenicol | 25 mg/mL | 25 µg/mL | Ethanol |

| Kanamycin | 50 mg/mL | 50 µg/mL | Water |

| Spectinomycin | 50 mg/mL | 50 µg/mL | Water |

| Tetracycline | 10 mg/mL | 10 µg/mL | Water |

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for PicoArray Fabrication and Agar Preparation

| Item | Function/Description | Example/Specification |

|---|---|---|

| SU-8 Negative Photoresist | Used to create high-resolution masters (molds) for PDMS-based PicoArrays via photolithography. | SU-8 3010, SU-8 3050 [1] |

| PDMS Elastomer Kit | The base material for soft lithography. Provides optical clarity, gas permeability, and flexibility. | Sylgard 184 [1] |

| LB Broth Powder | A rich, complex growth medium providing essential nutrients for a wide range of bacteria. | Composition: 5.0 g Yeast Extract, 10.0 g Peptone, 10.0 g NaCl per 37g pre-mixed powder [15] |

| Agar Powder | A polysaccharide derived from seaweed that forms a gel matrix, providing a solid support for microbial growth. | 12 g per L for standard plates [15]; 1.5% for agar sheets [1] |

| Antibiotic Stocks | Selective agents added to agar to isolate or select for microorganisms carrying specific resistance genes. | See Table 2 for concentrations. Prepare as 1000x stocks [15]. |

| Sterile PDMS Chamber Mold | A custom mold used to cast the replaceable agar sheets to the precise dimensions required by the PicoArray chip. | Internal dimensions: 76 mm × 26 mm × 1 mm [1] |

Integrated Experimental Workflow for Digital Plating

The power of the digital plating platform is realized when the fabricated PicoArray device and prepared agar sheets are used together in a seamless workflow.

Digital Plating Workflow

- Bacterial Suspension Preparation: Grow bacteria to the desired growth phase and dilute to the target concentration in a suitable buffer like normal saline [1].

- Sample Loading and Partitioning: Introduce the bacterial suspension into the inlet port of the PicoArray device. A pre-degassing-induced vacuum (self-pumping mechanism) drives the partitioning of the sample, distributing individual bacterial cells into the thousands of picoliter-scale microwells [1] [11].

- Agar Sheet Application: Carefully place the pre-prepared, sterile agar sheet onto the surface of the loaded PicoArray chip, ensuring full and uniform contact. This creates a "cover" that supplies nutrients and creates a microconfined environment for each trapped cell [1].

- Incubation and Imaging: Place the assembled unit in an appropriate incubator. The microconfinement within the picowells leads to accelerated metabolite accumulation, enabling detection and quantification in as little as 6-7 hours for E. coli, compared to 16-24 hours with traditional plating [1]. The platform is compatible with real-time, single-cell resolution imaging.

- Dynamic Assays via Agar Replacement: A key feature of the platform is the replaceability of the agar cover. To perform antibiotic susceptibility testing (AST) or change growth conditions, the initial agar sheet can be carefully peeled off and replaced with a new sheet containing the desired compounds (e.g., antibiotics). This enables rapid phenotypic screening (e.g., AST in <6 hours) without disturbing the spatially fixed microcolonies that have grown in the picowells [1].

High-Throughput Single-Cell Isolation from Complex Microbial Communities

Within the broader research on digital plating platforms for high-throughput microbial analysis, the precise isolation of individual microbial cells from complex communities represents a critical foundational step. Traditional culture-based methods, while considered the "gold standard," are hindered by prolonged incubation times, labor-intensive workflows, and an inherent inability to resolve cellular heterogeneity [1]. This document details integrated application notes and protocols for two advanced, complementary technologies enabling high-throughput single-cell isolation: a Digital Plating (DP) Platform and Single-Cell Sequencing via Semi-Permeable Capsules (SPCs). The Digital Plating platform bridges the gap between conventional microbiology and modern microfluidics, allowing for phenotypic screening and cultivation [1] [11]. In parallel, single-cell sequencing using SPCs provides a powerful tool for genotypic analysis, overcoming limitations of droplet-based systems by enabling full reagent exchange and multi-step workflows [16]. Together, these methods empower researchers to dissect microbial communities with unprecedented resolution.

Technology Comparison and Selection

Selecting the appropriate high-throughput isolation method depends on the experimental goals, whether they lean towards rapid phenotypic screening and cultivation or deep genotypic characterization. The table below summarizes the key characteristics of the two primary technologies discussed in this document.

Table 1: Quantitative Comparison of High-Throughput Single-Cell Isolation Technologies

| Feature | Digital Plating (DP) Platform | Single-Cell Sequencing (SPCs) |

|---|---|---|

| Core Principle | Microfabricated picoliter microwell array with replaceable agar sheets [1] | Encapsulation of single cells in semi-permeable capsules for DNA processing [16] |

| Throughput | 113,137 microwells per array [1] | ~100,000 cells per run (with lambda=0.1) [16] |

| Isolation Resolution | Single-cell isolation from mixed communities [1] | Single-cell encapsulation for genomics [16] |

| Key Applications | Rapid quantification, AST (<6h), microbial interactions, cultivation [1] | Linking antimicrobial resistance genes to host species, uncovering microbial diversity [16] |

| Typical Duration | E. coli quantification: 6-7 hours [1] | Multi-day process including lysis, amplification, and sequencing [16] |

| Cell Recovery | Facilitates recovery of cells for further analysis [1] | Not designed for cell recovery; focus on genetic material |

| Data Output | Phenotypic (growth, inhibition, susceptibility) | Genomic (taxonomy, ARGs, phylogenetic relationships) |

Application Notes

Digital Plating for Phenotypic Screening

The Digital Plating (DP) platform is a hybrid system that integrates the simplicity of traditional agar plating with the precision of digital microfluidics. Its core component is a high-density array of picoliter-sized microwells fabricated in PDMS. A bacterial suspension is loaded and partitioned into these wells via a self-pumping mechanism driven by a pre-degassing-induced vacuum. A critical innovation is the use of a replaceable, nutrient- or chemical-laden agar sheet that covers the array, creating a microconfined environment for growth [1]. The replaceability of this agar sheet allows for dynamic manipulation of the microenvironment during an experiment. For instance, an initial non-selective medium can be swapped for an antibiotic-laden one to perform rapid Antibiotic Susceptibility Testing (AST) in less than 6 hours. This platform dramatically accelerates microbial quantification—reducing the time from 16-24 hours to 6-7 hours for E. coli—by enhancing metabolite accumulation within picoliter wells, enabling faster detection of microcolonies [1]. Its applications extend to single-cell isolation from mixtures, selective enrichment using differential media, and quantitative studies of microbial interactions [1].

Single-Cell Genomic Analysis with Semi-Permeable Capsules

For comprehensive genotypic insights, single-cell sequencing using Semi-Permeable Capsules (SPCs) is a powerful complementary technique. This method addresses key limitations of traditional droplet microfluidics, where reagent exchange is difficult and workflows are constrained by reaction compatibility [16]. The SPC technology involves encapsulating single bacterial cells from a complex sample (e.g., sewage or feces) within permeable hydrogel capsules. A major advantage of SPCs is their semi-permeable membrane, which allows for complete exchange of reagents and waste products through simple washing steps, while retaining large genomic DNA fragments inside [16]. This capability is crucial for the multi-step workflow required for single-cell genomics, which includes cell lysis, whole-genome amplification, and combinatorial barcoding. The process enables the sequencing of genetic material from tens of thousands of individual bacterial cells in parallel. This high-throughput approach has been successfully applied to link antimicrobial resistance genes (ARGs) to their specific bacterial hosts within complex samples, thereby unraveling true microbial diversity and functional potential at the single-cell level [16].

Detailed Experimental Protocols

Protocol 1: Single-Cell Isolation and Analysis Using the Digital Plating Platform

This protocol describes the procedure for isolating and phenotypically characterizing single bacterial cells from a mixed community using the DP platform.

Table 2: Key Reagent Solutions for the Digital Plating Protocol

| Reagent/Material | Function | Example/Specification |

|---|---|---|

| PDMS PicoArray Device | High-density microwell array for single-cell partitioning | 113,137 hexagonal wells (70 μm diagonal, 40 μm height) [1] |

| Agar Sheet with Nutrients | Solid growth medium for microbial cultivation | LB broth with 1.5% agar; can be supplemented with antibiotics or indicators [1] |

| Liquid Growth Medium | For bacterial subculture and suspension preparation | e.g., LB broth [1] |

| Normal Saline | Diluent for adjusting bacterial concentration | 0.85-0.9% NaCl solution [1] |

| Antibiotic Stock Solution | For AST or selective enrichment | e.g., Ampicillin sodium salt, 100 mg/mL in distilled water, filter sterilized [1] |

Procedure:

- Device Preparation: Fabricate the PicoArray device using conventional soft lithography with SU-8 photoresist molds and PDMS (silicone elastomer: curing agent, 10:1 w/w). Cure at 90°C for 1 hour [1].

- Agar Sheet Preparation: Prepare a liquid agar medium (e.g., LB with 1.5% agar), autoclave, and cool to 60°C. Add any required reagents (e.g., antibiotics, dyes). Pour the mixture into a sterile chamber mold (76 mm × 26 mm × 1 mm), cover with a plastic sheet, and allow it to solidify at room temperature [1].

- Sample Preparation: Grow bacterial strains (e.g., E. coli, S. aureus) from frozen stocks in liquid medium. Harvest cells in the late exponential phase and dilute the suspension in normal saline to the desired concentration for single-cell loading [1].

- Device Loading: Introduce the prepared bacterial suspension into the main channel of the PicoArray device. The pre-degassed PDMS will create a vacuum, autonomously pumping and partitioning the suspension into the microwells via a network of loading microchannels [1].

- Incubation and Analysis: Carefully cover the loaded microwell array with the prepared agar sheet to create the cultivation microenvironment. Incubate the entire assembly at the appropriate temperature (e.g., 37°C). Monitor microcolony formation over time using microscopy. For dynamic assays like AST, the initial agar sheet can be replaced with a new one containing the antibiotic after initial growth is observed [1].

Protocol 2: Single-Cell Genomic Sequencing via Semi-Permeable Capsules (SPCs)

This protocol outlines the steps for preparing single microbial cells from complex communities for high-throughput genomic sequencing using SPCs.

Table 3: Key Reagent Solutions for the SPC Sequencing Protocol

| Reagent/Material | Function | Example/Specification |

|---|---|---|

| Detergent Mix | Cell detachment from complex samples | 100 mM EDTA, 100 mM sodium pyrophosphate, 1% (v/v) Tween 80 [16] |

| Lysis Enzyme Cocktail | Degrades cell walls for DNA release | Lysozyme, Zymolyase, Lysostaphin, Mutanolysin in PBS [16] |

| Proteinase K | Protein digestion for comprehensive lysis | 1 mg/mL in PBS [16] |

| Alkaline Lysis Solution | Chemical lysis to complement enzymatic treatment | 0.4 M KOH, 10 mM EDTA, 100 mM DTT [16] |

| Whole Genome Amplification (WGA) Mix | Amplifies genomic DNA within SPCs | Custom Single-Microbe DNA Barcoding Kit [16] |

| SPC Innovator Kit | Core reagents for capsule generation | Includes core/shell solutions, emulsion breaker [16] |

Procedure: